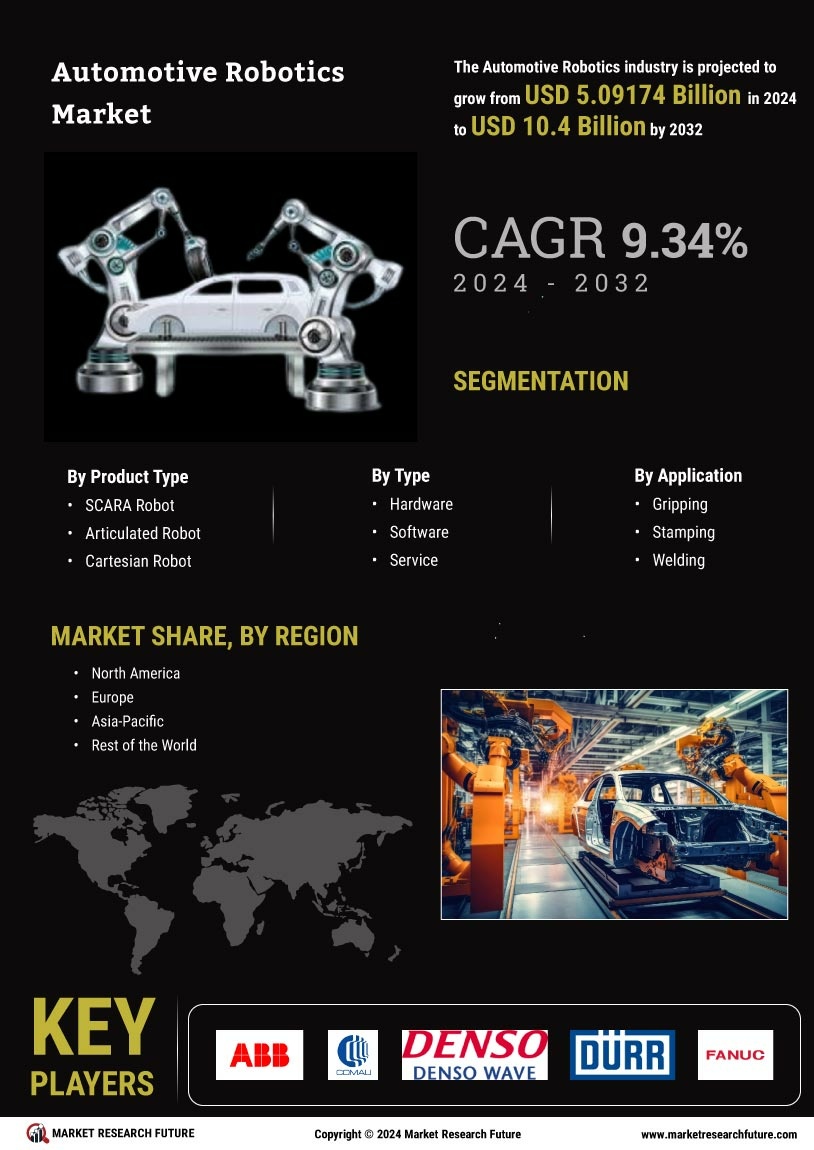

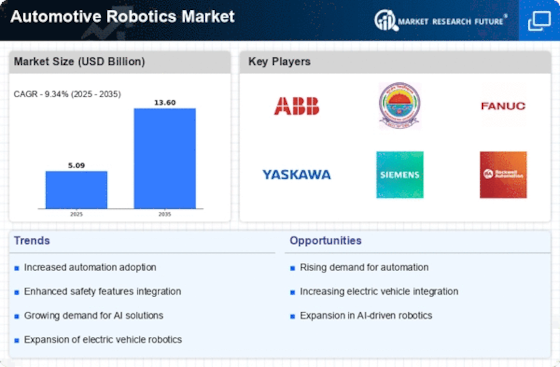

The Automotive Robotics Market is currently characterized by a dynamic competitive landscape, driven by rapid technological advancements and increasing demand for automation in manufacturing processes. Key players such as ABB (Switzerland), KUKA (Germany), and FANUC (Japan) are strategically positioned to leverage their expertise in robotics and automation. ABB (Switzerland) focuses on innovation and digital transformation, emphasizing the integration of AI and machine learning into their robotic solutions. KUKA (Germany) has been actively pursuing partnerships to enhance its product offerings, while FANUC (Japan) continues to expand its global footprint through strategic acquisitions and localized manufacturing initiatives. Collectively, these strategies contribute to a competitive environment that is increasingly focused on technological differentiation and operational efficiency.

In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and enhance supply chain resilience. The Vehicle Manufacturing Robotics Market appears moderately fragmented, with a mix of established players and emerging startups. The collective influence of key players is significant, as they drive innovation and set industry standards, thereby shaping the Automotive Robotics Market structure and competitive dynamics.

In August 2025, ABB (Switzerland) announced the launch of a new line of collaborative robots designed specifically for the automotive sector. This strategic move is likely to enhance ABB's Automotive Robotics Market position by addressing the growing demand for flexible automation solutions that can work alongside human operators. The introduction of these robots is expected to streamline production processes and improve operational efficiency for automotive manufacturers.

In September 2025, KUKA (Germany) entered into a strategic partnership with a leading automotive manufacturer to develop advanced robotic solutions for electric vehicle production. This collaboration underscores KUKA's commitment to innovation and positions the company to capitalize on the burgeoning electric vehicle Automotive Robotics Market. By aligning with a major player in the automotive sector, KUKA is likely to enhance its technological capabilities and expand its Automotive Robotics Market reach.

In July 2025, FANUC (Japan) unveiled a new AI-driven robotic system aimed at optimizing assembly line processes in automotive manufacturing. This development reflects FANUC's focus on integrating artificial intelligence into its robotics solutions, which could significantly improve productivity and reduce operational costs for manufacturers. The introduction of AI capabilities positions FANUC as a leader in the automation space, potentially reshaping competitive dynamics in the Automotive Robotics Market.

As of October 2025, current trends in the Auto Robotics Industry are heavily influenced by digitalization, sustainability, and the integration of AI technologies. Strategic alliances among key players are increasingly shaping the competitive landscape, fostering innovation and collaboration. Looking ahead, it is anticipated that competitive differentiation will evolve, with a shift from traditional price-based competition to a focus on technological innovation, supply chain reliability, and sustainable practices. This transition is likely to redefine how companies compete, emphasizing the importance of advanced technologies and strategic partnerships in driving future growth.

In October 2025, NIO confirmed new chip licensing and development partnerships with automotive and robotics firms. These collaborations aim to accelerate intelligent vehicle technologies and boost chip supply resilience. The move supports NIO’s long-term strategy in autonomous and smart EV systems.

Recently, NVIDIA highlighted major robotics and AI advancements at an international automation event, demonstrating next-gen industrial robots powered by GPU-accelerated perception and simulation. The showcase emphasised AI’s growing role in autonomous manufacturing and mobility automation.